SX Collets

The best effective TIR in the Industry!

Pioneer SX Collets, TIR - 3 Microns (0.0001")@ 4 x Diameter!

- SX Taper is 8 Degree, 1/2 the angle of ER

- SX Collets have a flat head locking surface, the locking nut has no influence on TIR

- SX Collets have 30%+ more surface engagement in the collet chuck for superior driving torque

- Interchangeable with industry SK collet systems

SX collets are offered in 2 classes

- Precision - SX

- SX Precision 5 Microns @ 3D (0.0002” @ 4D) & Anti-Rust Coating

- Ultra Precision - SX-P, Hand Inspected in 3 Axis before they ship!

- SX-P Ultra Precision 3 Microns @ 4D (0.0001” @ 4D)

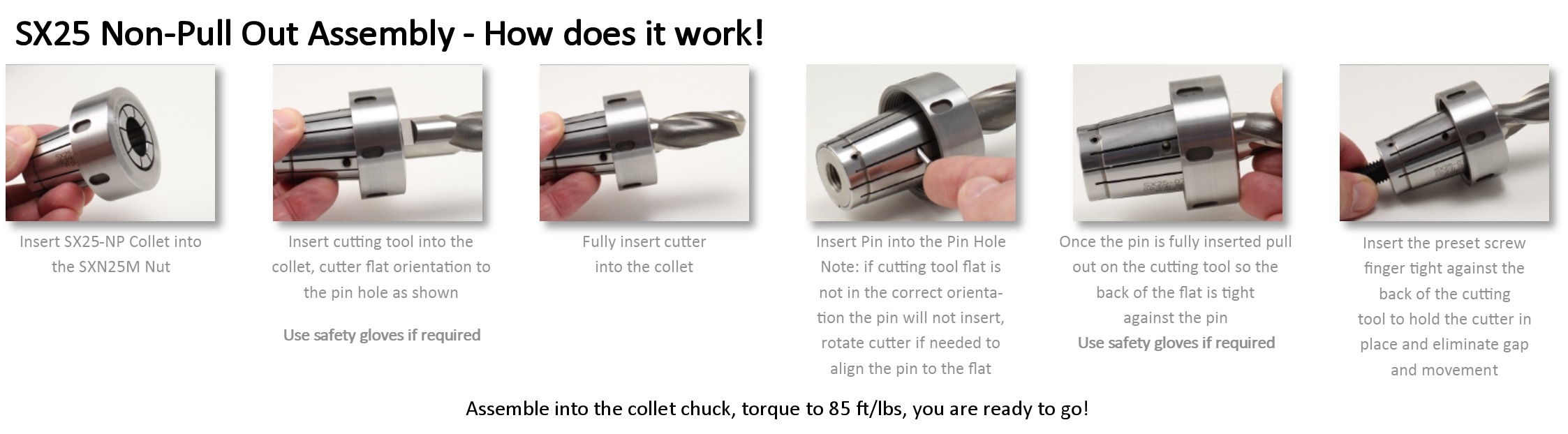

SX25 Non-Pull Out Collets

For Hi-Feed, Hi-Helix Milling Applications

Non Pull out collets are developed for hi-feed titanium and aluminum applications with a cutter helix of 45° or greater to prevent cutter pull out.

Weldon flat shown in the picture, any flat, groove, notch in a workable position can be used with SX-NP.

The Pioneer design utilizes a standard hardened 62Rc 3mm dowel pin to provide contact across the flat and superior sheer strength. The preset screw is used to hold the cutter in position, preventing any movement while being locked into the tool holder. The modification is performed at our location in Chicago, the pin location can be adjusted to fit any flat or groove position within the collet bore behind the nut. Special configurations available upon request.