Shell Mill Holders

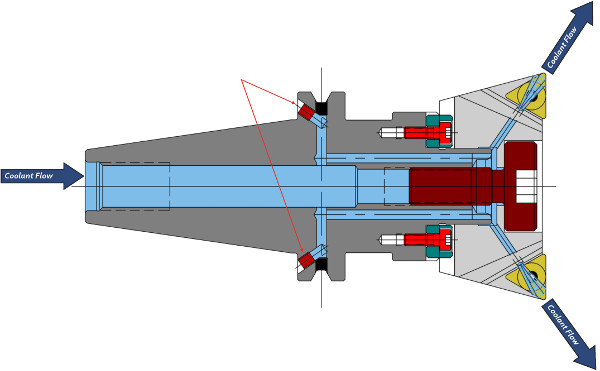

- Coolant Thru the Center

- DIN AD+B Flange Coolant Included in some models

- FX Coolant Ports Versions Available

- 30, 40 & HSK63A - G6.3 @ 20,000 RPM (without cutter)

- 50 & HSK100A - G6.3 @ 15,000 RPM (without cutter)

- Tapers are ground better than AT3 for optimal T.I.R.

Coolant Thru

Dynamically Balanced

ISO AT3 Taper Tolerance

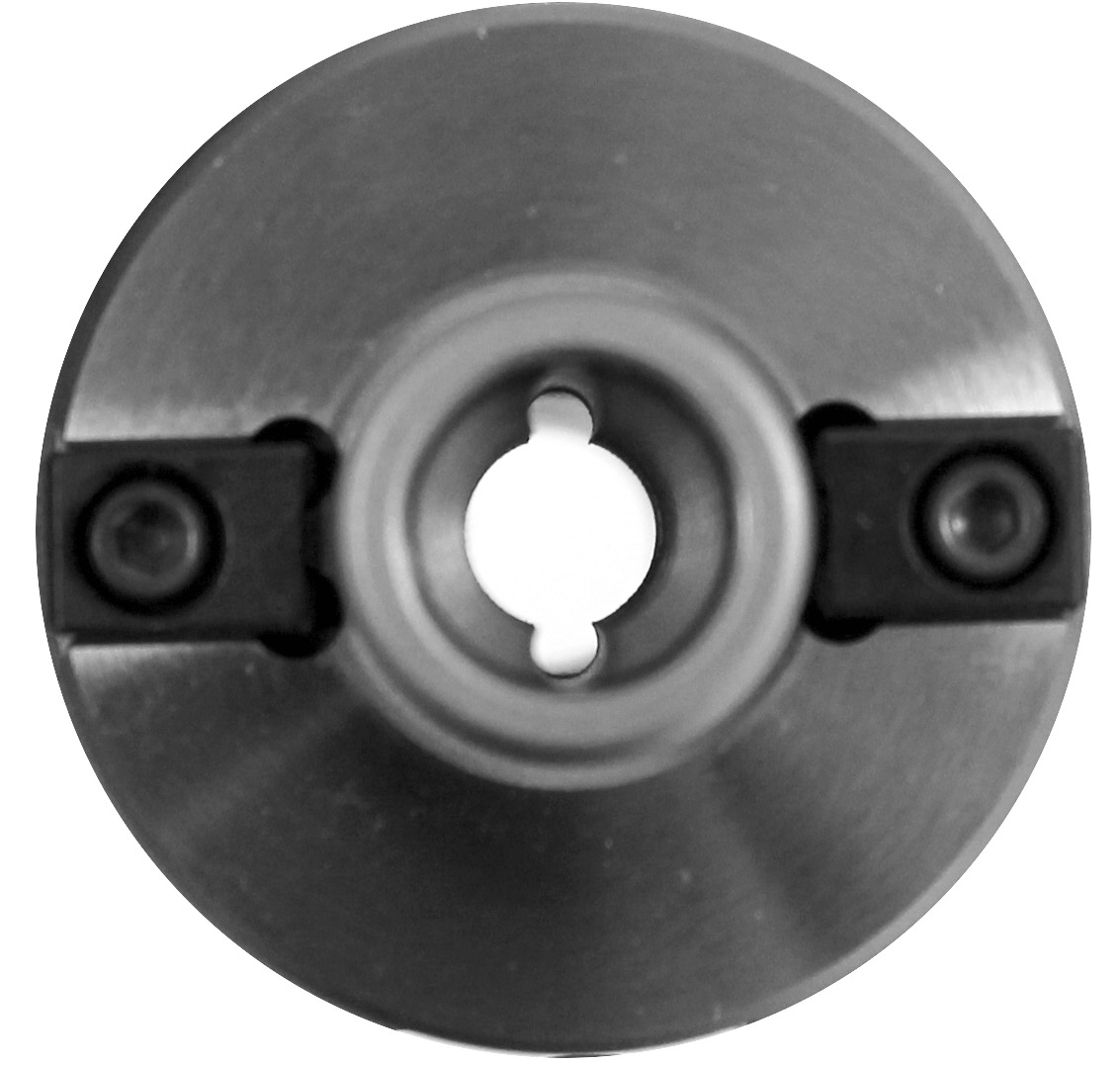

FX Coolant Option

Many cutter manufacturer's have standardized on what we call "Ported Coolant". This system delivers coolant to each insert from the relief in the mounting pilot area of the cutter. To supply coolant to this region many manufacturer's have altered mounting screws with drill holes. This approach works but limits the amount of coolant that can be delivered to the cutter.

The size of the drilled holes are so small they cannot deliver enough coolant volume to evacuate chips at high feeds. FX was designed to be used with the cutter manufacturer's supplied screws to increase coolant volume 400%+ for high feed cutters.